Holman Shaking Tables

- Unit is driven by the unique Holman head motion with variable stroke length between 8mm and 16mm (nominal) and internal components splash lubricated from an enclosed oil bath

- Simple, robust design requiring minimal maintenance

- Fully supported across the entire deck structure on 42 individual flexible straps allowing the deck to move throughout its stroke range precisely and consistently

- Table decks are constructed from high quality timber and highest specification plywood, completely sealed from water ingress with nominal 5mm rubber cover for maximum durability (white or black option available)

- Different riffle patterns can be supplied to maximise metallurgical performance. Riffles are all securely pinned using stainless fasteners (we do not bond or mould as part of construction). This maintains a super sharp profile for metallurgical performance, with no corrosion of fixings.

- Table tilt can be easily adjusted using a hand wheel, even while the machine is in operation

- Choice of concrete plinth or steel base mountings

- All feed/product launders are polyurethane lined for abrasion resistance

- All steels galvanised (BS EN1461)

- Fitted 1.5kW IP56 motor

A Holman 2000 operating at a metallurgical testing facility

The Holman 2000 conducting successful gravity separation test work.

An artistic impression of how the Holman table operates

The unique angle driven deck, with its saw tooth, shake profile provides the best separation of fine minerals

Why a Holman Table?

The Holman table we produce today is the culmination of extensive research and development in the fine minerals sector. Its ability to spread complex mineral streams and split close specific gravity minerals along the concentrate edge is unparalleled in its field.

This makes it the only choice for final grade and recovery in many situations.

The reason for this is the uniquely developed motion created by the Holman head which is in turn imparted onto the deck in conjunction with the 42 flexible support straps. This design maximises the hindered settling of the mineral within the feed stream. The resulting separation is peerless within the mineral processing industry.

The Holman shaking table technology has been proven time and again on multiple different global projects to be the world leading separator for fine minerals. From gold in Alaska to tungsten in Tasmania, the Holman tables are successfully upgrading and separating various minerals across the globe.

Holman shaking tables have been accepted by the mining industry as the best.

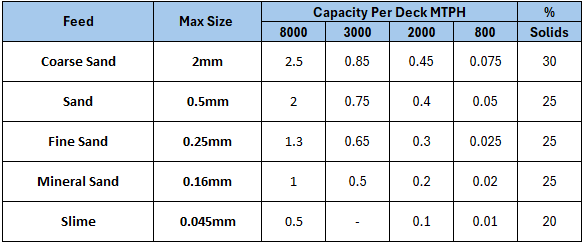

Holman Table Capacities

The Holman Shaking Tables have an industry leading capacity on a varied range of sizes and feeds.

Please note a cleaner table will have approximately 50% of the capacity of a roughing table.

Request a Quote today

Contact our Sales Team for a quote